Körber - Pharma Packaging Machines by Mediseal

BE the step ahead.

The future is uncertain. Constant change becomes part of our daily lives. The ability to quickly adapt day-to-day operations to ever-changing requirements has never been more important for a company to thrive and grow.

Welcome to our world of flexible packaging solutions, where faster is the new speed limit. Make adaptability your new competitive advantage:

- high product quality and production efficiency

- high machine uptimes and robust output capacity

- easy cleaning and short changeover times

BE the step ahead.

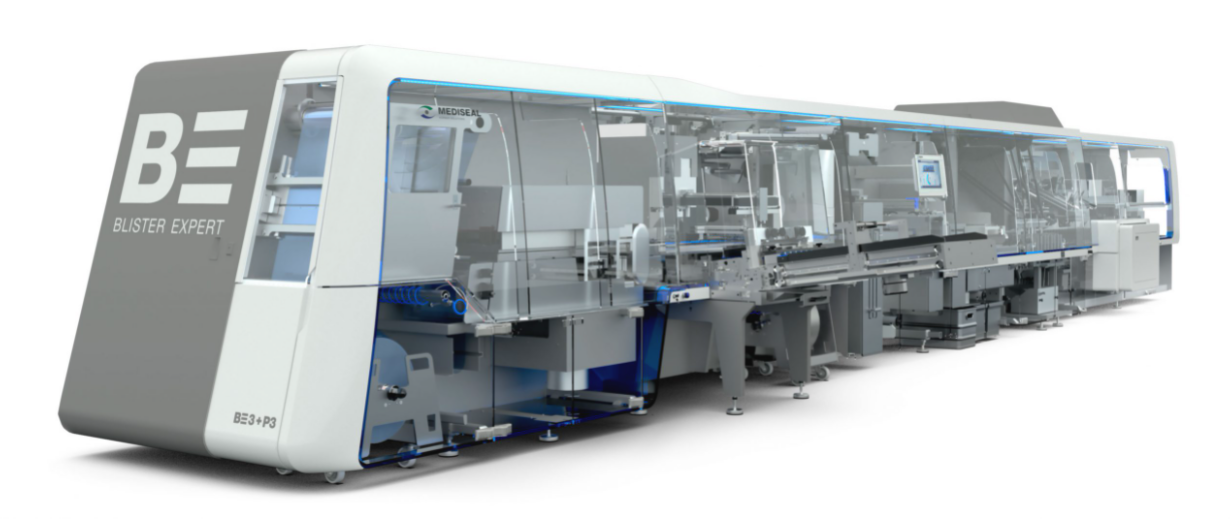

The modular specialist.

Less and less time for production with ever greater demands on quality and format variability of primary and secondary packaging? This requires flexible solutions. And these are exactly what Blister Expert BE offers in perfect combination with the P3 cartoner: its development incorporates Mediseal’s more than 80 years of experience in blister and packaging technology. The system can be individually adapted to the needs of the customer: it was developed to be completely modular

This makes the Blister Expert very flexible — and new products can be on the market very quickly. In addition, change-over and maintenance times have been shortened.

Future-proofing through 100% modularity.

Blister lines for oral solids: pioneering and versatile

Short production times, flexible solutions and the best quality are daily requirements in the competitive environment of the international pharmaceutical industry. The consistent modular design of our blister machines enables machines to be tailored flexibly to your needs. Modular construction means clear separation of zones and optimal accessibility to the different areas. Even difficult materials can be processed reliably and in accordance with GMP standards. Several hundred machines world-wide testify to this successful approach.

Körber’s blister machines are designed to meet the following requirements of the pharmaceutical industry:

- Blister Expert BE4: agile & robust for all applications on a small footprint

- Blister Expert BE6/BE8: powerful & inuitive for high-speed up to 800 blister/min.

- Clinical studies and small lot sizes (CP200)

- Classic applications (CP400)

- High output, 1- or 2-track (CP600)

- Highest output and large format width (CP1200)

Blister lines for medical products: flexible and efficient

When it comes to individually developed, future-proof and versatile blister lines for medical products, Körber is the right partner for you. With our packaging solutions, we support you at all times in meeting the constantly changing requirements of a demanding industry. This also applies to newly added formats or products. Designed for nearly one hundred percent technical runtime and efficiency, we offer you flexible solutions that allow you to respond to changes immediately.

Körber’s medical product blister machines are designed to meet the following requirements:

- Blister Expert BE3:versatile & future proof

- Blister Expert BE5: Powerful & Intuitive

- As a compact solution without limitations on format and choice of film (CP2)

- As a robust general-purpose solution with multiple configuration options (CP3)

- For high output when packaging challenging products (CP500 series)

Appropriate sachet solutions for your pharmaceutical and cosmetic products.

Decades of experience in the production of sachet packaging machines combines with dosing systems of our own design for demonstrably high dosing accuracies. Mediseal's vertical sachet machines are intended for packaging your high-quality pharmaceutical and cosmetic products.

The range of possibilities and output ranges is extensive. Anything is possible with 2 to 16 tracks. GMP-compliant, of course. And an appropriate transfer solution to a sideload cartoning machine is guaranteed.

Körber’s sachet machines are designed to meet the following requirements:

- For clinical studies and different dosing systems (LA160)

- As a high-output solution, ideal for granulates (LA500)

Machines for uncomplicated production of stickpacks

Stickpacks are becoming more and more popular with consumers, because they find them convenient. The product is perfectly portioned and can be taken quickly and simply, even on the go.

For manufacturers, stickpacks have promising possibilities, especially in terms of differentiation from the competition. The products can be fully printed on our machines, providing surfaces for brand messages right down to the primary packaging. For the same fill quantity, stickpacks consume up to 40% less material than sachets.

With its stickpack line, Körber presents an excellent solution for the primary and secondary packaging of free-flowing powders, granulates, pellets and liquids. The line is based on the existing LA600 SP stickpack machine. This was developed specifically for the needs of the pharmaceutical market. Intelligently linking together the LA600 SP and the P1600 cartoner, which has already notched up high sales, creates an ideal combination of proven technologies.

The range of possibilities and output ranges is extensive. Anything is possible with 2 to 16 tracks. GMP-compliant, of course. And an appropriate transfer solution to a sideload cartoning machine is guaranteed.

Körber’s sachet machines are designed to meet the following requirements:

- For clinical studies and different dosing systems (LA160)

- As a high-output solution, ideal for granulates (LA500)

Sideloading cartoner for blister packs, sachets, and similar.

To ensure that blisters, ampoules, vials and similar reach patients safely and in compliance with GMP, packaging machines for secondary packaging must meet high requirements. The sideload cartoners from Körber are perfectly adapted to this. The flexible, modular machines allow effortless expansion of a blister, sachet or stick pack systems into a complete, high-performance production line.

- P2/180 intermittent motion cartoning up to 150ppm for large packs

- P2/P4 intermittent motion cartoning up to 300ppm on a small footprint

- P3 continuous motion cartoning up to 300ppm for versatile applications

- P5 continuous motion cartoning up to 500 ppm for high performance

- P1600/P3200 intermittent motion cartoning up to 300ppm for medium batch sizes

Related information

Business website:

Relatd industries:

Related Techniques:

Contact Us!

Have any questions? You would like us to call you back?

Send us the following blank sheet. Our staff will contact you soon.