Bilfinger Industrietechnik Salzburg GmbH.

Bioreactor systems and fermentation equipment

Our bioreactor line represents the essence of our expert knowledge and has been designed with the utmost care. It is built using high quality, state-of-art components and is equipped with user-friendly E/I&C, automation and software. Whether for bacterial fermentation or cell culture, a Bilfinger bioreactor offers the right solution.

As a global leader in the area of infection control, Belimed has offered the most recent products specialised in cleaning, disinfecting and sterilizing to the healthcare, pharmaceutical and laboratory sectors for 40 years now.

Bioreactors for Laborator Use

Mobile lab bioreactor system

- Working volume: 15 to 100 L

- Mobile and compact design

- Dual mobile control unit

- On-site sterilizing of push valves for additions

- User conform process visualization

- PAT-compliant hardware design

- Application: laboratory, R&D, education

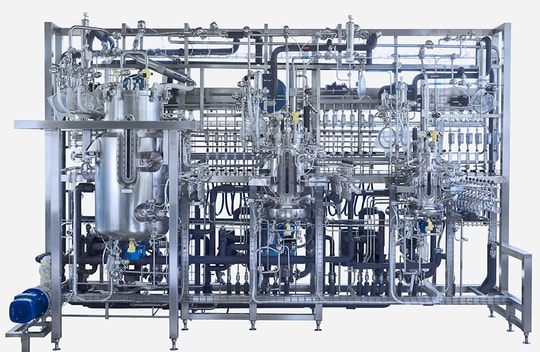

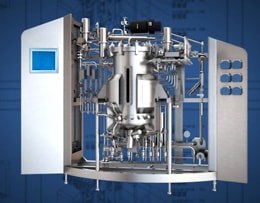

Pilot Bioreactor Systems

Pilot bioreactor system

- Working volume: 100 to 1,000 L

- Flexible scalability

- Modular and space-optimized design

- Central control unit

- Integrated CIP unit, optional

- Fully automated hardware configuration

- Application: pilot plant

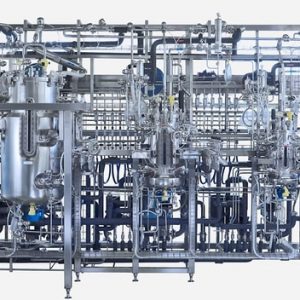

Production bioreactor systems

Bioreactor system for production

- Working volume: from 1,000 L

- Complete production plant

- “Super skid” manufacturing

- Steel platform construction

- High qualification standards

- Application: production

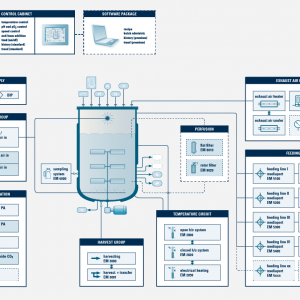

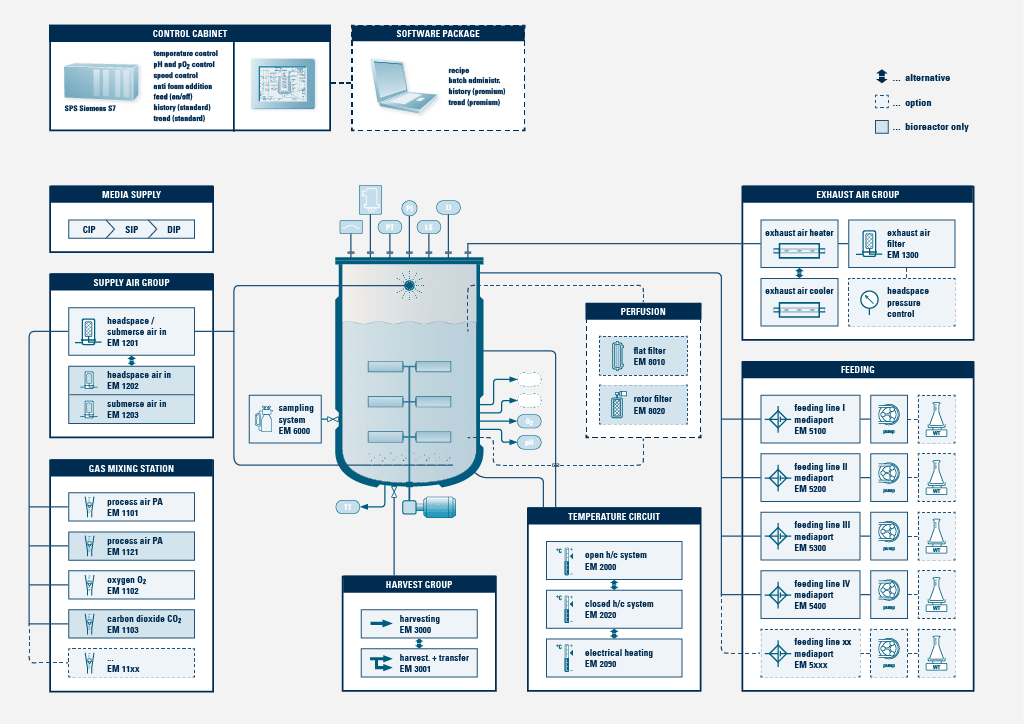

Modular system for bioreactors and fermenters

An intelligent module system combines the advantages of series-manufactured products with the benefits of bespoke solutions. Established and reliable modules are available for all main functions. The customer can select what he needs to assemble a system to perfectly match his requirements. The module system offers short lead times and delivery periods due to the fact that the majority of engineering and development of the module system is already finished.

The Modules

Gas mixing station

Supply air group

Exhaust air group

Temperature circuit

Sampling system

Feeding

Harvest group

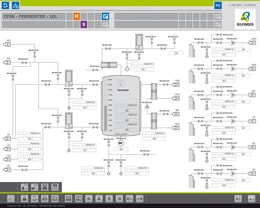

User friendly software.

The bioreactors are fitted with a user-friendly software system which is touchscreen-operated.

USER-FRIENDLY DESIGN

All functions and displays for operating the bioreactor system can be readily seen and accessed on the front of the equipment.

Your own individual offer!

The modular system is structured in such a way that individual specifications can be implemented swiftly and simply. We will be pleased to provide you with a quote for the bioreactor tailored to your specific requirements.

Contact us for your own individual offer!

Solution preparation systems

Whether you require mobile solution preparation containers or fixed systems, semi or fully-automated operating models – our engineers will develop a bespoke solution for each task, complying with sterility requirements and satisfying all rules and regulations with respect to qualification and validation.

The modular structure of the components permits user-friendly handling, while the use of proven components ensures stable operations.

The plant modules are prefabricated in Salzburg and tested and prequalified under operating conditions. In this way, it is possible to achieve the shortest possible installation and start-up phases.

CIP/SIP systems

The cleaning process plays a crucial role in the pharmaceutical and biotechnology production process. Only by ensuring reliable cleaning before and after each production step is it possible to satisfy the demanding quality requirements.

Numerous different forms of execution are possible depending on the process, the available media, the operating models and the validation requirements. Energy-efficient and low-maintenance executions as well as optimised turnaround times in tandem with consistently high cleaning performance form the basis of our plans.

Bilfinger plans, fabricates and installs CIP/SIP systems for:

Fixed process equipment

Mobile equipment (e.g. mobile vessels)

Small parts

Execution types:

- Integrated CIP models (operating tank = target tank)

- Multi-tank systems (acid, lye, pure-water requirements) with or without rinsing water recycling

- Detergent dosage systems

- Hygienic heat exchangers for tempered CIP steps

- EX execution also possible

- Sterilisation activities subject to temperature-monitoring and logging

- Bespoke automation and visualisation models

The plant modules are prefabricated in Salzburg and are tested and prequalified under operating conditions. In this way, it is possible to achieve the shortest possible installation and start-up phases.

Display of a CIP/SIP control system

Gallery

Related Information

Business website:

Related Indurties:

Related Technology:

Contact Us!

Have any questions? You would like us to call you back?

Send us the following blank sheet. Our staff will contact you soon.