Packaging Machines

Monomaterial packaging machines for the pharmaceutical industry.

Top-loading packaging solutions with partition

At Körber, we package pharmaceutical products more than safely: beyond that our packaging solutions are sustainable, environmentally conscious and patient-friendly.

Your benefits:

- Flat cardboard partition blanks – printable on both sides

- Secure automated erecting and gluing

- Secure product insertion process (100% verification after insertion)

Over the entire manufacturing and logistics process, this results in concrete advantages for you as a manufacturer of parenterals as well as your end customers, which positively influence both your Total Cost of Ownership (TCO) and your Total Cost of Package (TCP).

Some examples for product packaging with TOPLoading

Vials and ampoules

2×5 vials in upright position – easy opening

1ct vial TopLoading – side opening

2ct Ampoule NeoTOP 804 – Triple technique

3 vial trays in 3x5ct dispenser package – NeoTOP x

Syringes: prefilled – safety – backflow prevention

2×5 prefilled syringed vaccine – World star award-winning packaging!

Prefilled syringes – dispenser package

Safety syringes with different flanging

Syringe package with compact product protection and flight safety characteristics – flight safety

Pens – Injection needles – Inhalers

Pen package with lid closing

Compact pen – NeoTOPx

Inhalers of any shape

Nasal sprays

Combined packages

Combined package – ampoules and vials

Combined package – syringes and vials with advertising space – folding cover

Syringe and vial package – NeoTOP 804 – Triple technique

Combined syringe package – Needle holder – Blister

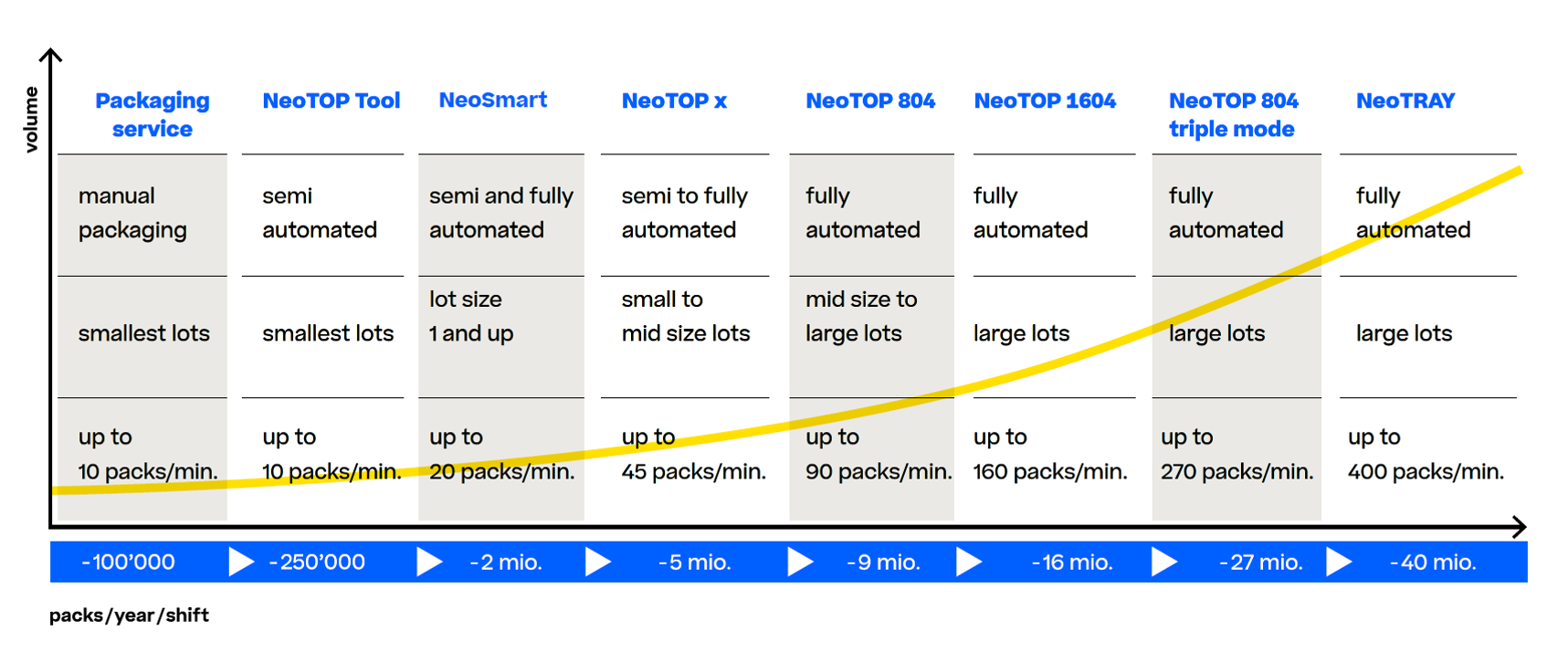

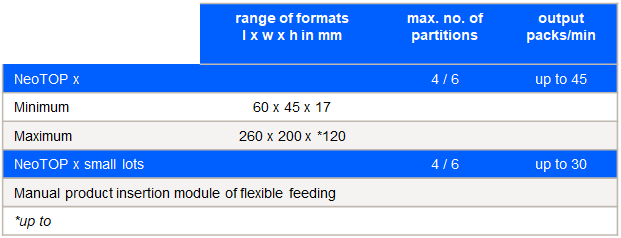

Dividella NeoTOP x - always adapting to your requirements

Modular and expandable, the Dividella NeoTOP x can be adapted to the specific requirements of pharmaceutical product manufacturing. It is ideal for the production of small to medium batch sizes.

Technical Details:

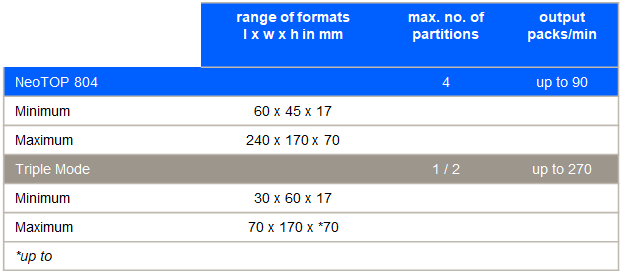

Dividella NeoTOP 804 - for medium to large batch sizes

The Dividella NeoTOP 804 can easily handle up to 270 packs per minute (in triple mode). Like all the machines in the NeoTOP family, it can be expanded or retrofitted with additional modules and infeed systems. This makes it ideal for the processing of a wide range of products while maintaining top performance.

Technical Details:

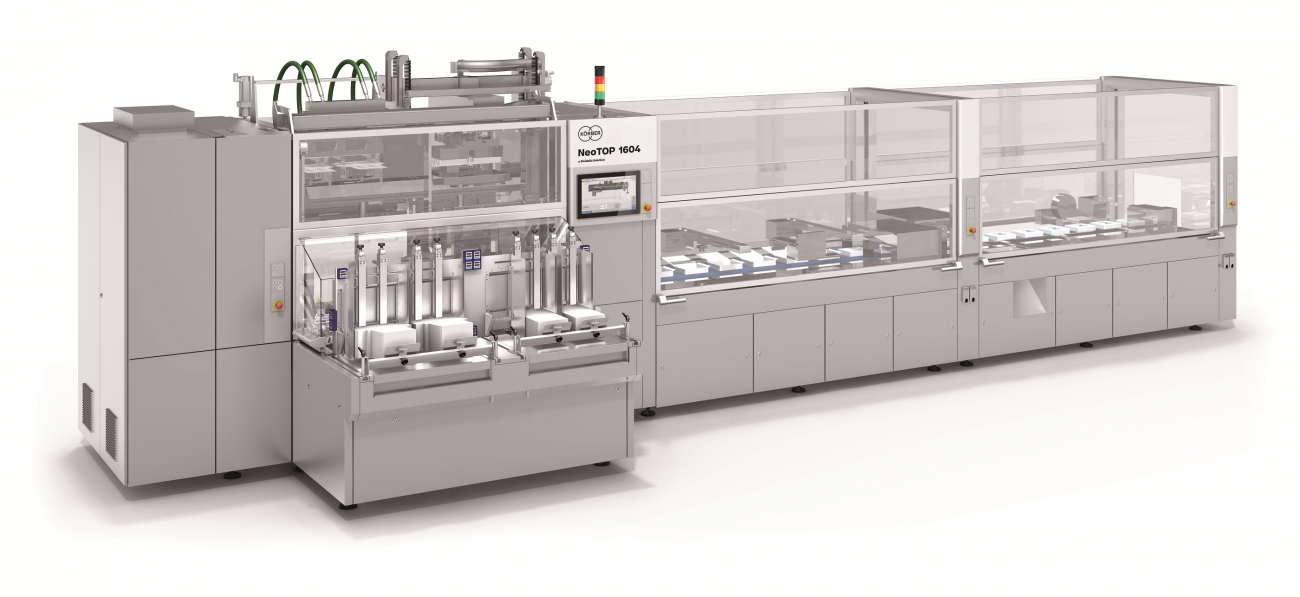

Dividella NeoTOP 1604 - speed and flexibility for large batch sizes

Two-packs, three-packs and four-packs — demand is growing and at the same time requires higher cartoning speeds. Our Dividella NeoTOP 1604 combines high output with maximum flexibility. It can accelerate the production of large batches up to 16 million packs per year. Thanks to the modular design of the NeoTOP family, including the infeed systems for products and booklets, you do not have to commit to one application.

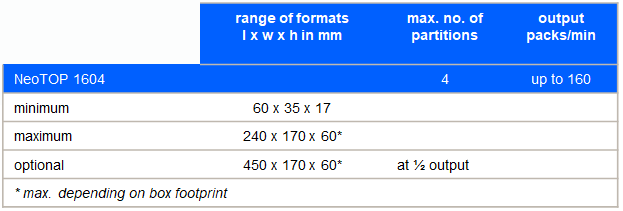

Technical Details:

Dividella NeoSmart — flexibility and quality for small batch production

With the Dividella NeoSmart solution, Körber offers a modular and expandable packaging system that is not locked into one implementation. We enable flexible and efficient production, especially for low-volume applications. And thanks to the FlexUnits, a fast, online format change is possible - without line clearance.

Technical Details:

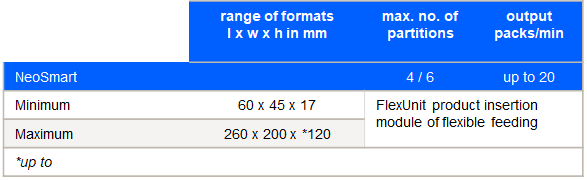

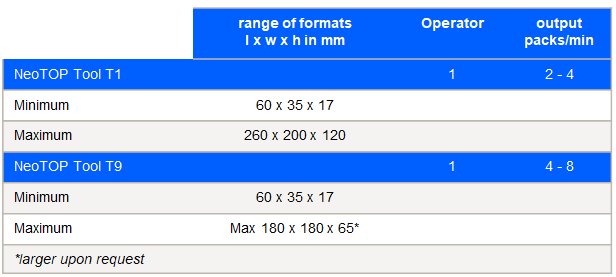

Dividella NeoTOP Tool — effortless entry into the toploading process

For the packaging of very small quantities and clinical studies, you are on the safe side with the carton erector (Dividella NeoTOP Tool T1) and carton sealer (Dividella NeoTOP Tool T9). Both units are GMP-compliant and ensure easy and safe handling. The reliable cold gluing of the Dividella NeoTOP Tool from Körber can be converted to hot gluing as production volume increases. With the same mono-material packaging style, this enables seamless up-scaling to semi- or fully-automatic topload cartoners.

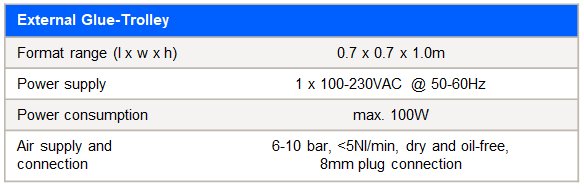

Technical Details:

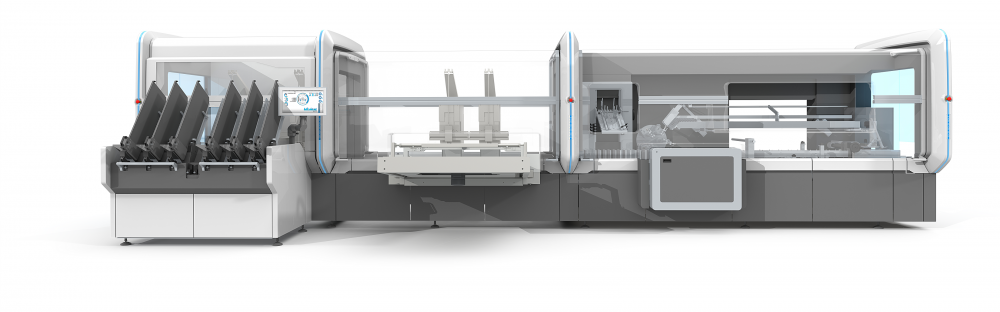

Side-loading cartoners with divider blank

Dividella NeoTRAY

The best of both worlds: sideloading and toploading from a single source

This high-speed system is suitable for a wide range of applications: Parenteral drugs in the form of vials, syringes, injectors, pens, ampoules, cartridges, inhalators, nasal sprays, and other systems can be securely packed in large volumes.

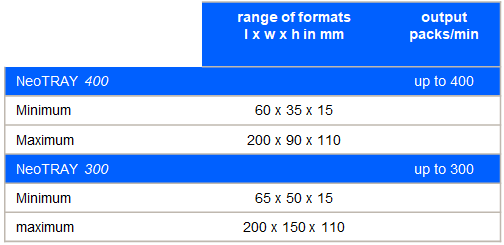

As a manufacturer, you respond to new requirements at any time and serve the market. With its high speed, the Dividella NeoTRAY can process up to 400 individual products or multipacks per minute and reliably adapts to a wide range of formats. In addition, the machine uses the proven advantages of mono-material and produces the packaging from 100 per cent economical and sustainable cardboard.

Technical Details:

Related information

Business website:

Relatd industries:

Related Techniques:

Contact Us!

Have any questions? You would like us to call you back?

Send us the following blank sheet. Our staff will contact you soon.