KÖRBER Pharma – Inspection Solutions by Seidenader

Inspection solutions for top quality requirements

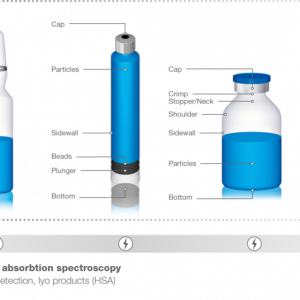

Whether pharmaceutical or biotech products in liquid, highly viscous or freeze-dried form; Whether syringes, vials, ampules or cartridges: We know the stringent requirements that sensitive products and fragile containers place on transport systems as well as the demands that our inspection technologies pose for handling. We offer you the optimal solution for all of your inspection needs, enabling you, as a manufacturer, to ensure that only flawless products leave your facilities.

More than the sum of its parts

Our high-performance machines with state-of-the-art inspection technology for the most demanding requirements in the pharmaceutical and biotech industry.

Each of our inspection machines from Seidenader Solutions combines three core competencies: The inspection forms the heart of the machine. Handling is the hand, while the control is the brain, which ensures that all components interact smoothly. The result is more than the sum of its parts: Innovative inspection solutions — every challenge can be solved.

One idea, endless possibilities

Our Seidenader Solutions are characterized by modularity and flexibility that leave nothing to be desired - both within a machine and across the entire product portfolio.

Infinite applications, one software

The modules and machines are all controlled by uniform software and operated via a consistent HMI. In line with our motto “configuring rather than programming”, we can easily adapt new machines, upgrades, and retrofits to your wishes and requirements.

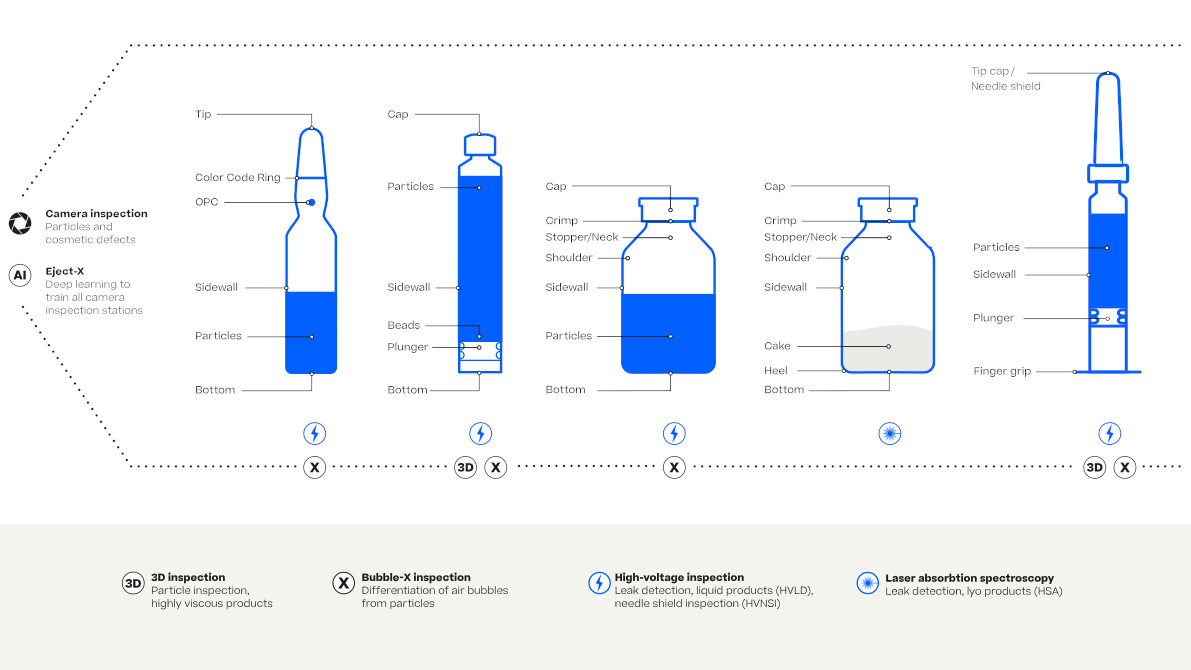

The appropriate technology for each product

More than 125 years of experience, one goal

Your high quality requirements are our benchmark. Since 1895 we have been developing solutions for the pharmaceutical industry with the objective: delivering the difference.

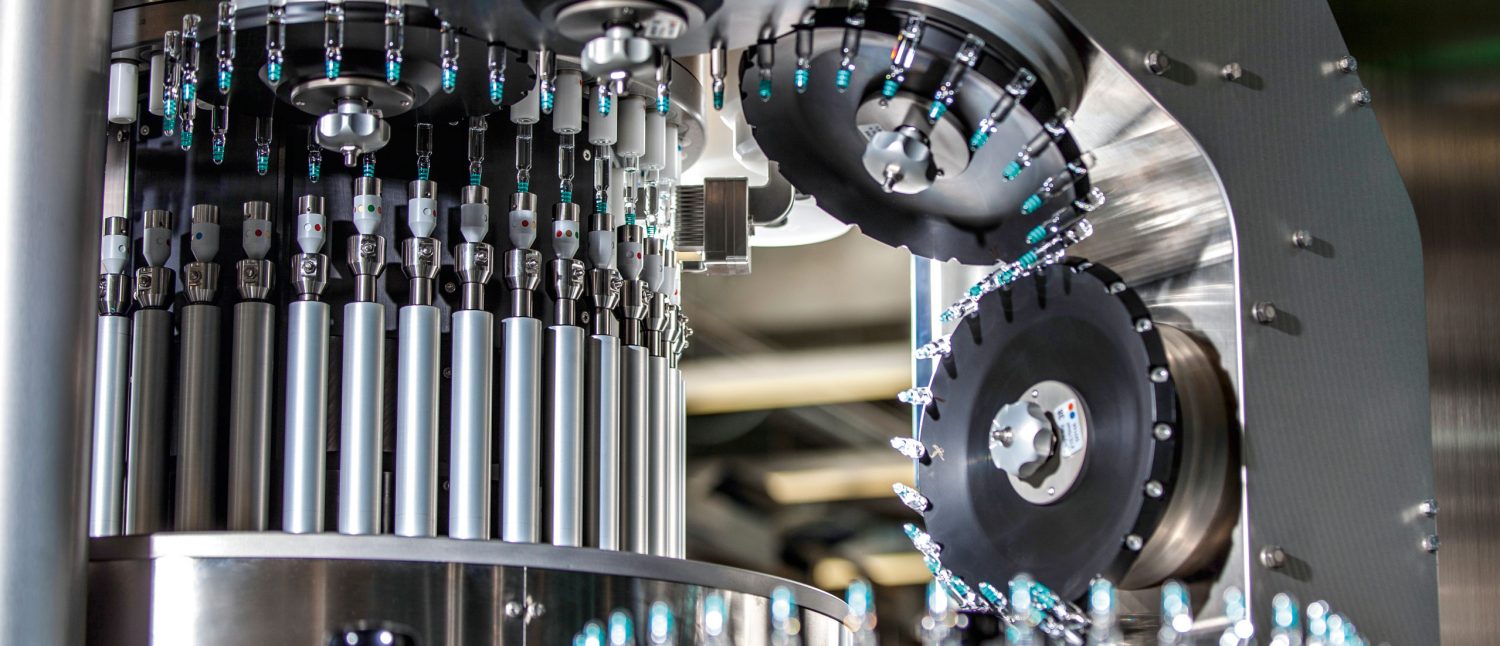

Automatic inspection

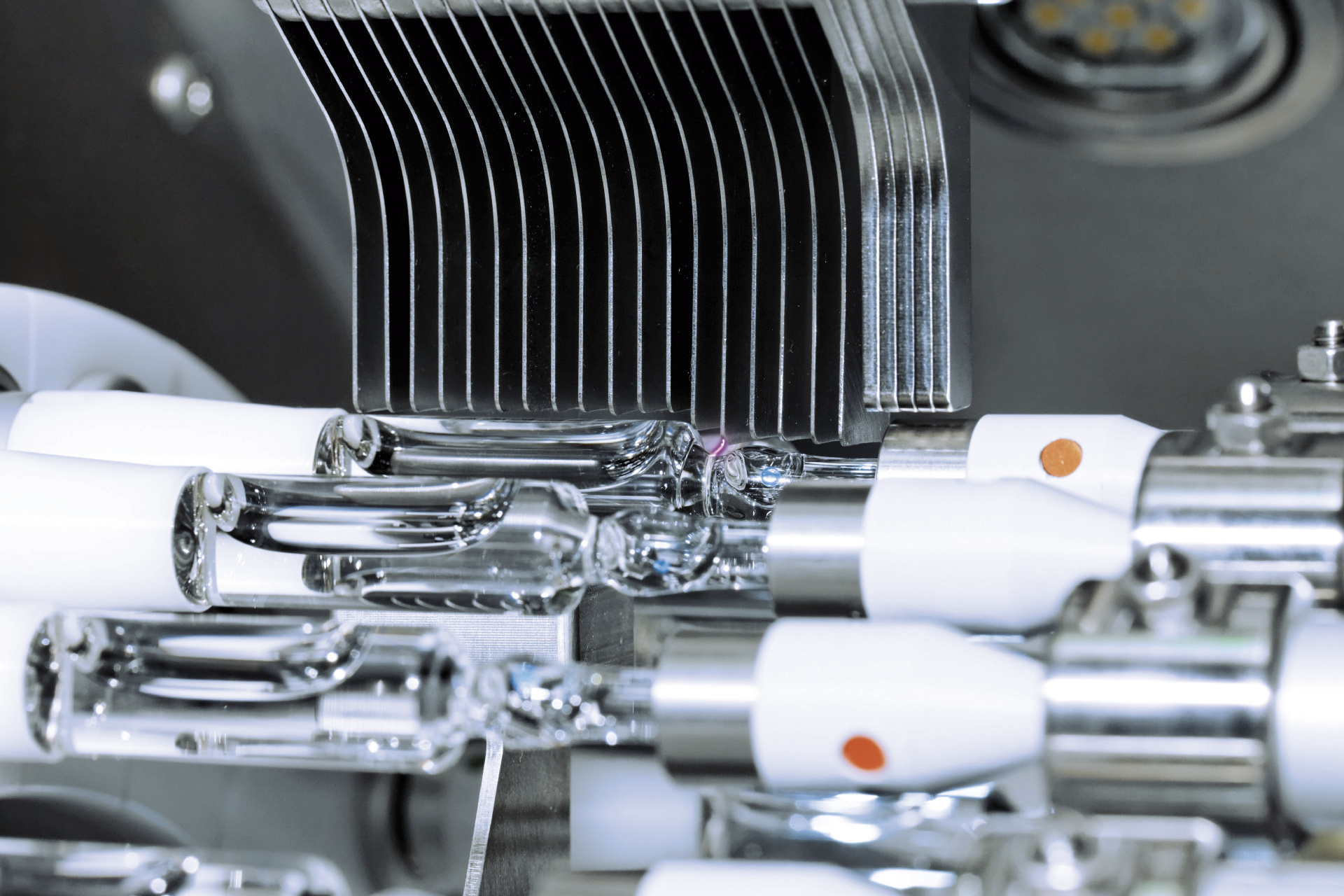

Perfectly matched: Our fully automatic inspection machines combine optimally adapted handling of your products, highly precise image processing, and innovative inspection technologies to achieve maximum efficiency.

Semi-automatic inspection

The perfect complement for your visual inspection: Our machines are flexible, ergonomic, and intuitive to operate.

Lab equipment

Monitor random samples from your production or test different camera settings, vary the lighting or try out various rotation speeds — without interrupting ongoing production. operations.

In-process inspection

Inspect empty glass containers before filling them with expensive pharmaceuticals. Control closures already during the filling process. Boost the efficiency and safety of your production by conducting quality checks before the usual final inspection takes place. We seamlessly integrate our inspection systems into your existing production process.

Line integration

Aside from supplying machines, we also develop holistic solutions that optimally fit your production process. Our services range from consulting to the integration of the associated machines, transportation systems, and software solutions to process optimization.

Precision from a single source: Automatic inspection

Are your products liquid, highly viscous or freeze-dried? Do you want to inspect syringes, vials, ampules or cartridges? We are aware of the high demands that your pharmaceutical and biotech products and their special containers place on transport systems. And we take into account the different handling requirements of our inspection technologies when developing all machines right from the start. With our Seidenader Solutions, we offer you the optimal solution for your inspection needs.

Machines and technologies: The choice is yours

Machine platforms as a basis for individual solutions

You want to inspect smallest batches of personalized medicine fully automatically, or a blockbuster around the clock? We have the right solution.

Inspection technologies for optimal results

Camera, high voltage, laser - with us you get the right technology for every product, matched to your containers and the desired inspection criteria.

Modules to combine: We make it fit

With standard modules to the special customer machine

Whether you want to detect leaks in ampules filled with viscous products, dispose of persistent drops at stoppers, or inspect normally filled vials of liquids for leaks, we have the right module for you.

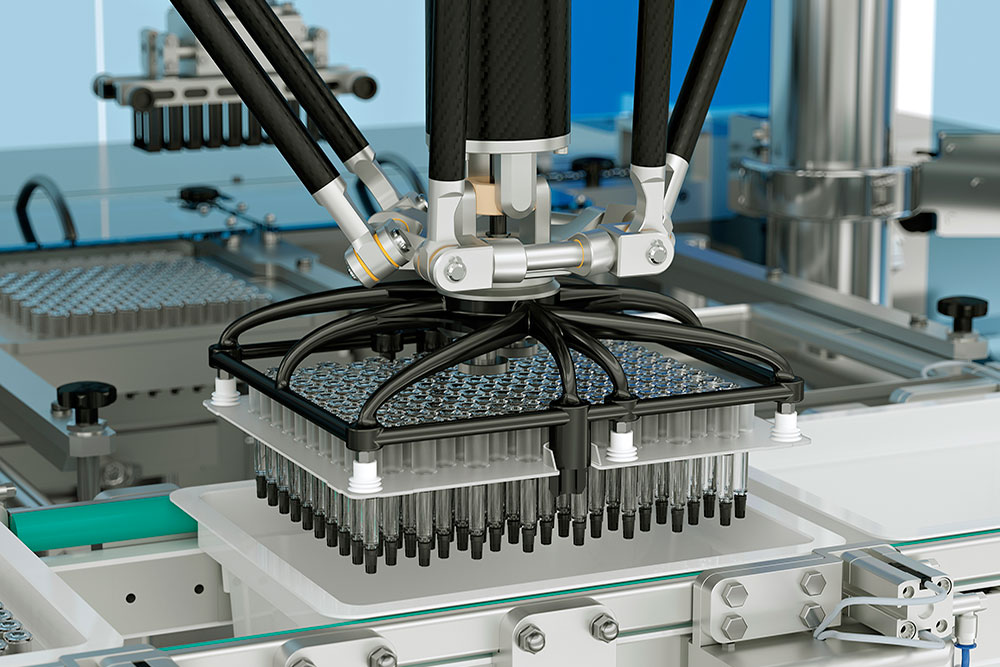

The Seidenader DE.SY.RE — our successful combination

Are your syringes delivered in nests or does the product react sensitively to touching or bumpy transport? Our combination of de- and re-nesting with high performance inspection will convince you.

Gallery

Related information

Business website:

Relatd industries:

Related Techniques:

Contact Us!

Have any questions? You would like us to call you back?

Send us the following blank sheet. Our staff will contact you soon.