Zeton B.V.

Pilot plants, lab scale systems, demonstrations plants, production plants

Lab scale Systems

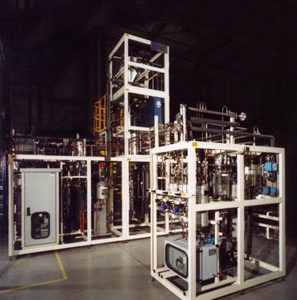

Zeton understands the critical importance of lab scale systems in process development. Dedicated manufacturing bays in Enschede and Burlington facilitate the fabrication of smaller systems. And our unique proven approach to designing and building lab scale systems ensures that completed projects meet or exceed our customers’ expectations and requirements.

Microreactor and small, laboratory-scale systems for catalyst testing can be designed and built with fixed bed, fluidized bed and/or CSTR reaction modules. From single to multi-reactor configurations, Zeton’s custom-designed small scale plant systems have been built to handle catalyst loadings of less than one gram as well as fractionation/recycle and integrated analytical capability.

Fully automated with customers’ preferred software, our bench top and skid mounted plants are delivered ready to run with complete engineering and operational documentation.

- Autothermal reformer lab scale system

- Four reactor hydrotreater lab scale system

- Stirred reactor synfuels lab scale system

- Hydrodesulphurisation catalyst testing system

- Two 7-fold catalyst testing high throughput experimentation plants

- ASTM steamer lab scale system

- High Throughput Experimentation Catalyst Testing Plant With 12 Individual Reactor/ Product Separation Sections

- Diesel exhaust testing unit

Pilot plants

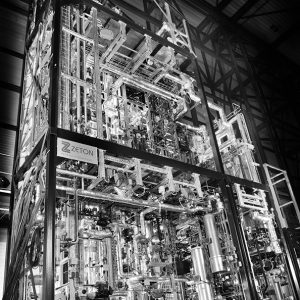

Since 1986, Zeton has designed and developed pilot plants that bridge the gap between bench-scale chemistry and commercial manufacturing. With over 750 completed projects, we are the largest and most successful pilot plant design and fabrication specialist in the world.

Our unique project execution methodology and purpose-built, integrated design-build facilities supply pilot plants that enable the scale-up and development of innovative process technology.

Zeton’s engineers and craft technicians take pride in translating our customers’ process technology into fully automated, working pilot plants. We provide specific equipment, control and instrumentation solutions across a wide variety of industries, customizing each pilot plant to deliver the necessary research results.

- Small scale continuous polypropylene pilot plant

- Crude Oil Distillation Pilot Plant

- Parallel Reactor Hydrotreater Pilot Plant Including Stripper

- Ebullated Bed Pilot Plant with H2 Feed Module

- Hydrodesulphurisation pilot plant

- Pressure oxidative hydrometallurgical pilot plant

- Gas to methanol pilot plant

- 8 parallel reactors hydrotreater pilot plant

- Dual reactor high throughput Fischer-Tropsch Pilot plant

- Gasoline Synthesis Pilot Plant

- Double Loop Reactor Polypropylene Pilot Plant

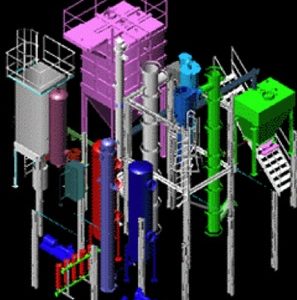

Small Modular Commercial Plants

Zeton applies its modular process plant design/build methodology and know-how to a variety of applications, including

- Small-volume specialty chemical production units

- Flow chemistry/continuous pharmaceutical plants

- Plants for producing market development quantities of new materials for established markets

- Pre-built modular process plants to replace or augment existing facilities where space is an important consideration

Modular fabrication can make economic sense for small commercial units where feedstock supply is only available in a remote location, or is only available or required in limited quantities. Biomass-to-ethanol and waste oils-to-biodiesel plants are processes which typically favor modular plant construction. Commercial specialty chemical and pharmaceutical plants can also fit into this scale, especially when they support continuous processing or batch-wise processing of small product quantities.

- Commercial scale biomass to bio-oil pyrolysis plant

- Electronic Chemicals Production Plant

- Biomass Pyrolyis Liquid Fuels Plant

- In Situ Fluorine Production Plant

- 60 million liter/year Biodiesel Plant

- High Viscous Resin Blending System with Jacketed Steam System

- Polystyrene Semi-Works Plant

Related information

Business website:

Relatd industries:

Related Techniques:

Contact Us!

Have any questions? You would like us to call you back?

Send us the following blank sheet. Our staff will contact you soon.