Az IWK új tubustöltő gépet installált az UHU ragasztók tubustöltésére. 1954 óta IWK gépekkel töltik az UHU ragasztókat.

Az IWK új tubustöltő gépet installált az UHU ragasztók tubustöltésére. 1954 óta IWK gépekkel töltik az UHU ragasztókat.

UHU is one of the best-known and most successful brands of glue in the world. The development of new materials, changes in usage and consumption habits, but above all UHU‘s own objective of being able to offer the right product for every type of glue job have led to the company now offering a range of over 50 kinds of glue. For school, kindergarten, home, office, trade and industry, for games, handicrafts, repairs, construction, model making and DIY, there is a UHU glue for every user – and every time in UHU‘s proven quality.

Today, UHU is part of the globally active Bolton Group. Together with its sister company BISON, from the Netherlands, UHU makes up the lion‘s share of the Bolton Adhesives division. The glue in its yellow tubes with their distinctive lettering has been produced in the Baden- Württemberg city of Bühl, near the border between Germany and France, for decades. Every year, millions of tubes leave the production facilities. IWK tube filling machines and packaging machines are in constant operation.

Task:

Delivery of a complete line for glues – a line that encompasses tube filling, cartoning and accessories packaging.

IWK solution:

FP 46/2 tube filling machine in combination with TZ 204 tube infeed and SC 4 horizontal cartoning machine with connected scales. Up to 220 tubes/min processed.

UHU PRODUCTION EXPANSION

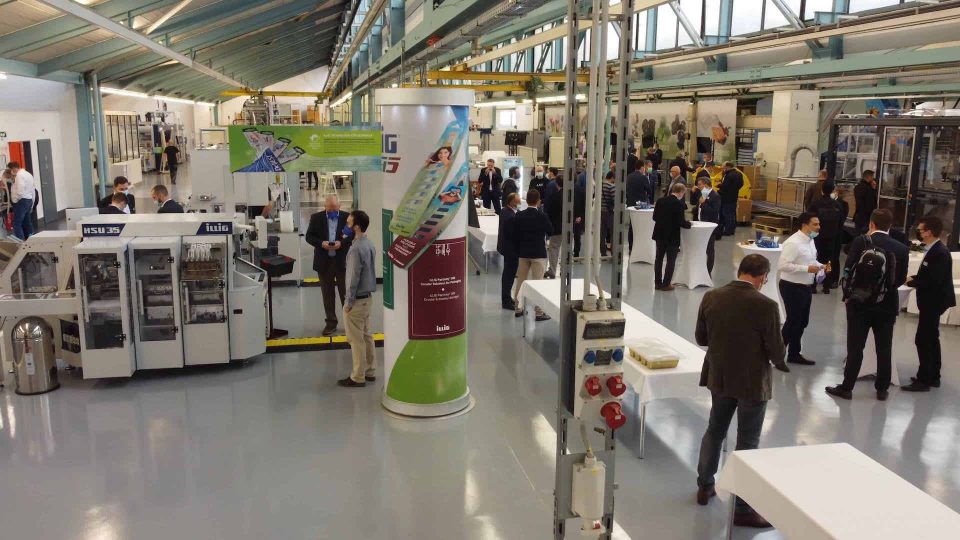

The latest expansion of the company‘s production capacities saw the installation of a complete line made up of tube infeed (TZ204), tube filling machine (FP 46/2) and an SC4 cartoning machine, which can process up to 450 boxes/minute. The perfectly coordinated line fills metal tubes with glue and then packs them in cartons. A later switch to filling plastic tubes is possible with relatively little outlay. To control the filling volume, the cartoning machine is connected to an OCS scales.

IWK systems at UHU have been reliably filling tubes with different glues and product variations since 1954. Most recently, 12 machines were in use: tube filling machines, horizontal cartoning machines, infeeds and other models. In addition to the advantage of IWK‘s geographical proximity to Bühl, it is above all UHU‘s positive experiences with IWK machines that have been the deciding factor in the long-standing business relationship between the two companies. And, at every encounter, UHU project managers are once again impressed by the down-to-earth, solutions- oriented approach of IWK engineers. Even the latest line to be delivered to UHU was completely modified to the customer‘s specification in order to respond to the glues‘ characteristics and UHU‘s safety requirements.

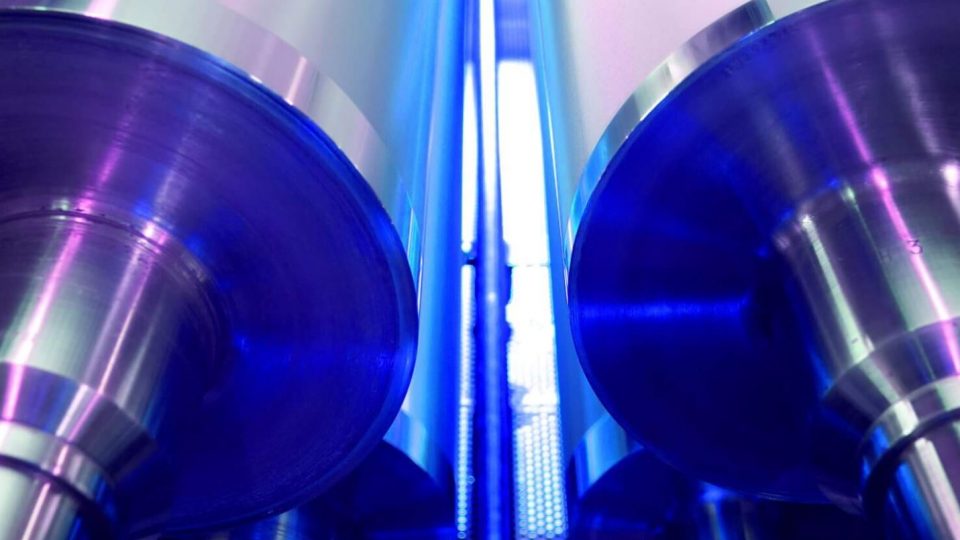

The consistency of the various glues means that special technologies and equipment are necessary. A specially designed filling device is required to ensure the individual metal tubes are filled cleanly and uniformly. The cleanliness of the filling process is crucial to the tubes‘ trouble-free further processing through to their final packaging in the carton. And, at the same time, the product cannot otherwise satisfy the manufacturer‘s high quality standards.

In addition to these product-specific requirements, IWK systems can be individually equipped for different configurations of the end product. In this case the tube is packed in the carton together with a UHU applicator tip. This allows the end user to apply the glue more precisely if need be.

To complete the project, it was necessary to overcome a serious logistics challenge when the system was installed. The planned place of installation for the line was on second floor of an already fully equipped production hall. It was therefore only possible to bring it into the building using a crane.

An experienced logistics partner used a lorry to hoist the line directly in front of the window openings on the second floor and maneuvered it into the building with with millimeter precision.

About IWK Verpackungstechnik GmbH

IWK Verpackungstechnik GmbH focuses on the efficient, precise, and attractive packaging of goods for the pharmaceutical, cosmetic, food, and chemical industry. IWK systems are used in industries with very exacting standards. The company has been known for its innovative and groundbreaking approach from its very early days. IWK currently holds a large number of patents for key technologies and each year invests significantly above the industry average in research and development, resulting in numerous innovations each year.

Further company information and contact details can be found on the company website at www.iwk.de