Blister foil pore detection from SCANWARE

Description

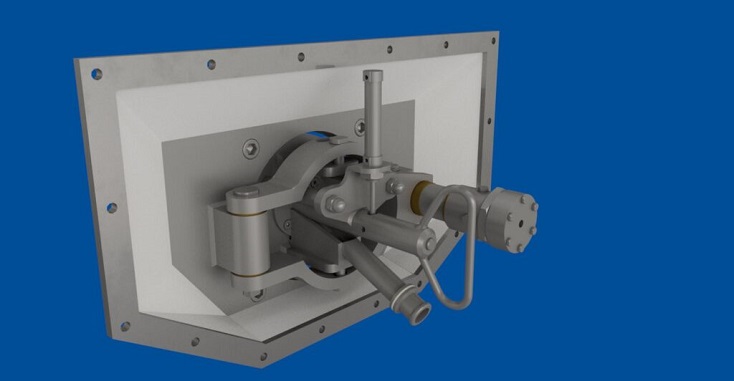

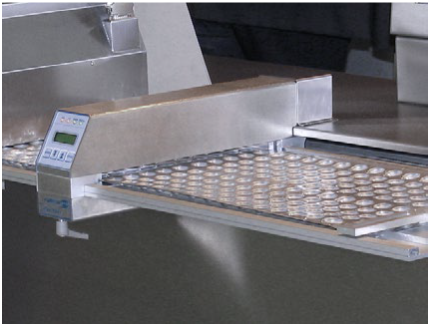

The system serves the optoelectronical inspection for the detection of pores and cracks in aluminium foil of up to 1,000 mm width. LYNX-FOCON is installed between the forming and the filling stations at a right angle to the travel direction of the foil.

If any pores are present, a signal is given to prevent filling and subsequent ejection occurs. The pore detection can run at the speed of up to 1.5 m/s, thus keeping step with all current blister machines.

Due to its internal fault monitoring capacities, LYNX-FOCON is self-monitoring, continuously checking system integrity. All outputs are short-circuit protected and designed for failsafe operation.

Area of Application

- Detection of pores and microfissures in aluminium bottom foil (formed or plane)

- Detection of pores and microfissures in aluminium lidding foil

For the use on machinery without a guide surface, an adapted mechanics can be supplied to minimize external light influences. This enables the use on stickpack-machines.

Highlights

- The system can easily be integrated onto any existing blister machine without machine reprogramming, avoiding extensive software re-validation, thus saving valuable time and costs.

- High detection capacity down to 25, 50, 100,250 and 500 μm.

- Internal shift register optional

- Increases cost-efficiency due to considerably reduced material waste

- Available in widths of 200 to 1,000 mm

- Multi-lingual display

System

LYNX-FOCON is configurable to either one or two zones of detection, depending on the blister machine layout. This unique feature splits the detection area along the central line of the foil material, allowing for discrimination of faulty blister packages. At the same time, material waste due to cracks and pores can be strongly decreased.

Sizes up to 1,000 mm available.

As a stand-alone unit with internal shift register (optional), LYNX-FOCON is capable of operating independently of the packaging machine. The shift register is easily programmed by the user.

Hardware

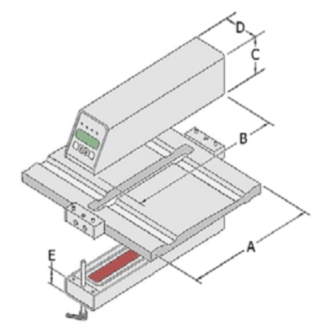

| FOCON 200 | FOCON 250 | FOCON 300 | FOCON 350 | FOCON 400 | ||

|---|---|---|---|---|---|---|

| A | mm | 100 – 200 | 200 – 250 | 250 – 300 | 300 – 350 | 350 – 400 |

| B | mm | 240 | 290 | 340 | 390 | 440 |

| C | mm | 76,2 | 76,2 | 76,2 | 76,2 | 76,2 |

| D | mm | 76,2 | 76,2 | 76,2 | 76,2 | 76,2 |

| E | mm | 30 | 30 | 30 | 30 | 30 |

Sizes up to 1,000 mm available

For more information on our products, please visit our website or contact directly:

Ferry Contact Ltd.

www.ferrygrp.com

info.hu@ferrygrp.com

T.: +36-1-348-6000

Source: www.scanware.de