INTEGRA® ISF the state of the art Form Fill and Seal machine for packaging food industry powder and granules

“The FFS machines available in the market today almost all look, feel and perform alike. In redesigning the INTEGRA® ISF, we need to do something different. We need to set us apart from the competition. We need to break barriers when it comes to performance, intuitive operation, availability and cleanliness.”

Peter Felling, IFS Project Manager

Haver & Boecker designed the INTEGRA® ISF as the next generation FFS to reach new heights when it comes to intuitive operation, performance, availability and cleanliness. The ISF version of INTEGRA® fulfills every performance requirement a customer may have. Its modularity ensures to be configured according to the actual needs, with the possibility of upgrades at a later point in time.

Based on the experience collected, it was clear that customers wanted a packaging system that can be operated easily and intuitively. It should be easy to understand, quick to learn and most importantly, it must communicate with the operator. The ISF accomplishes all these goals. Using LED „mood” lights, the machine state can be confirmed in a blink of an eye. Blue light indicates it is running fine. The red light tells it has a problem and the white lights helps in maintenance mode. The large touch-screen panel offers all the features at a click of a button. The user interface not only shows the error messages, but can show movies on how to repair them. The system can differentiate multiple access levels such as operator, maintenance or service technician. The HAVER QUATTRO technology also enables the remote monitoring of the machine conditions.

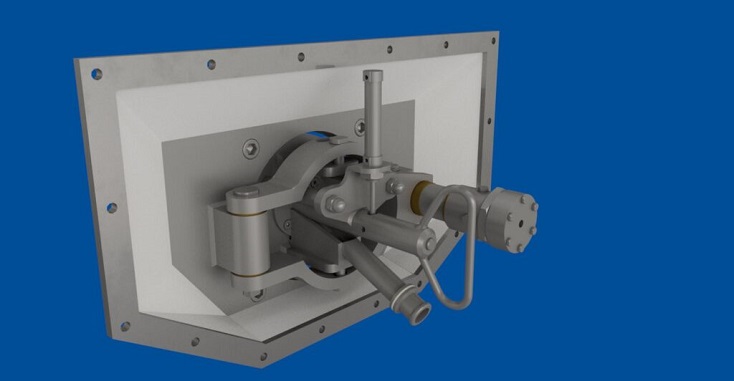

The INTEGRA® ISF is designed with your highest operation and maintenance comfort in mind. All components are easily accessible once the extra-large glass doors are opened. Critical parts are exchangeable using snap in place solutions.

In order to minimize set-up times, an automatic reel-changer is also available as option.

The INTEGRA® ISF is the best solution for packaging mixtures or granules in FFS film out of PE, woven PP or alu-laminated, 5 to 50Kg bag weights with a capacity up to 2.600 bags/ hour.