Lombardi Converting Machinery s.r.l.

The Italian idea of Flexo

The North Italy (Brescia) based Lombardi is a prosperous Company developing extraordinarily dynamically to become one of the leading flexo press machine manufacturers since its appearance on the market with the application of technical solutions worth of attention and with references certifying the successful delivery of more than 1300 machines (in 100 countries all over the world). It has been engaged in the designing and manufacturing of narrow web flexographic printing machines (centrally or line positioned counter press cylinder design) since the 2000s contributing to the development of printing companies, evolving “The Italian idea of Flexo”.

The recent machine supply ranges from the narrow web servo driven flexomachines through the diverse machines for finishing to hybrid digital label presses.

Flexographic printing machines

Flexographic narrow and mid-web presses built for high quality print. Thanks to their flexibility and smart electronics are highly efficient on many substrates (BOPP, PVC, PE, PET, paper, adhesive paper, thermal paper, cardboard, laminated materials ) supporting the operators with ultra-short changeover times.

INVICTA

is fully servo and gearless, with three servo motors for each printing unit, sleeve technology with automatic positioning, Hi-Dynamics for pneumatic pressure of the blade on the anilox roll for a perfect distribution of the ink.

Not only it is presented to the world of printers as "universal machine", i.e. without any limit of workable substrate (BOPP, PVC, PE, PET, paper, adhesive paper, thermal paper, cardboard, laminated materials) and as "smart", i.e. as having flexibility and dynamism to facilitate the operator and to minimize his efforts. Web width available in 450 mm, 550 mm, 650 mm and 750mm.

INVICTA i2

is fully servo and gearless, with three servo motors for each printing unit, sleeve technology with automatic positioning, Hi-Dynamics for pneumatic pressure of the blade on the anilox roll for a perfect distribution of the ink.

Not only it is presented to the world of printers as "universal machine", i.e. without any limit of workable substrate (BOPP, PVC, PE, PET, paper, adhesive paper, thermal paper, cardboard, laminated materials) and as "smart", i.e. as having flexibility and dynamism to facilitate the operator and to minimize his efforts. Web width available in 450 mm, 550 mm, 650 mm and 750mm.

SYNCHROLINE

For printers today, one of the greatest challenges are to print on extensible packing materials for the packaging industry.

The printing press is adjustable to the most diverse surfaces to be printed on to eliminate the common problems of printing and owing to accurate tension and temperature control most of the materials can be printed.

Fields of application: cartons, shrinking foils, shrinking foils used in food industry, multitier tags, extensible packaging materials, shrink sleeves, metallized foils, safety products, lottery tickets, brochures, RFID tags and tickets.

Each printing unit of SYNCHROLINE is equipped with an independent servo motor to ensure advantages such as the pre-register, auto-register and print length control.

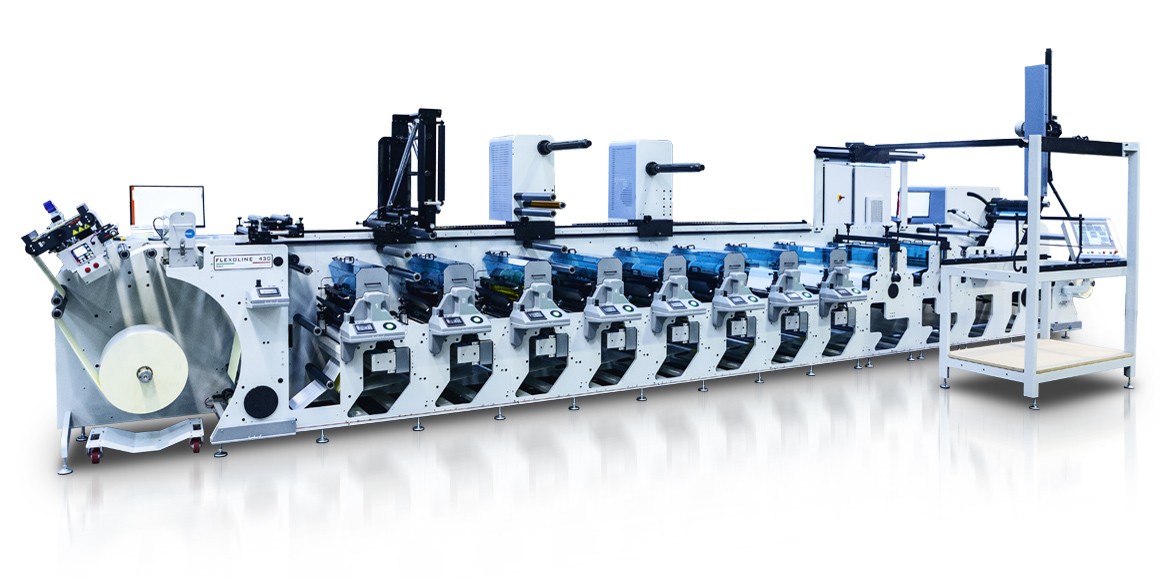

FLEXOLINE

Lombardi experience focuses on a high-tech narrow web machine in line destined for printers who look for high printing quality coupled with simple and fast job changeover.

The company has paid main attention on these two aspects of flexographic printing: the quality of images (which is now almost up to offset printing) and the fast changeover of impression cylinders and ink rollers.

And in the light of this need, Flexoline offers advanced technological solutions aimed at ensuring excellent printing register also with high speeds and granting ease of use.

MODULAR

Modular flexographic printing machines, equipped with standardized automation systems such as in-line flatscreen, embossing, hologram in-setting or different multi-layer and booklet processing units based on specific customer needs.

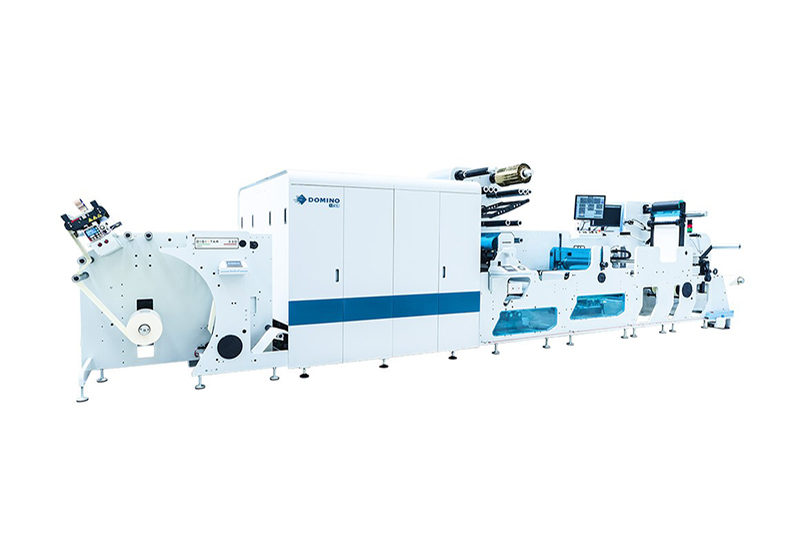

DIGITAL

Digital hybrid machine is combining the latest UV inkjet technology with the versatility of flexo and traditional high quality label finishing in one footprint.

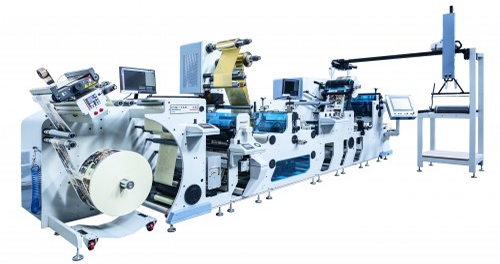

FINISHING

Machines developed for finishing of labels pre-printed with digital or other impression process. The modular concept allows options like flat screen, hot stamping, semi rotary hot foil with format correction and different types of diecutting.

DIECUTTING

Lombardi’s flat diecutting machines for labels, board and plastic cards are world famous about their precision and durability.

Gallery

Videos

Invicta:

Synchroline:

Flexoline:

Digistar Inkjet Hybrid:

Digistar Finishing:

Related information

Business website:

Relatd industries:

Related Techniques:

Contact Us!

Have any questions? You would like us to call you back?

Send us the following blank sheet. Our staff will contact you soon.