Mobile cleanroom solutions:

- New approach to cleanroom manufacturing space

- Fast and flexible

Standard width mobile cleanroom

Extended width mobile cleanroom

Main features

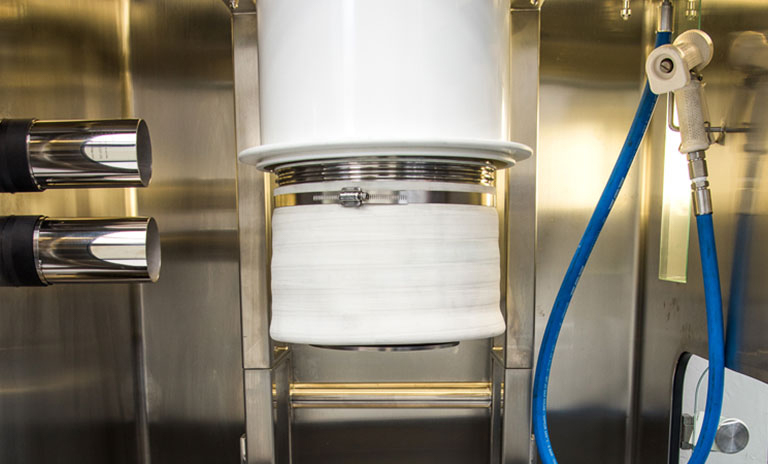

Our self-contained, ready-to-use design provides functional cleanroom space wherever and whenever you need it. Whether you want to expand manufacturing, R&D or processing capacity at an existing facility, a remote location, or around the globe, our MCRs can be transported and fully operational more rapidly than other cleanroom options. Extract Technology is pleased to add mobile cleanroom solutions (MCRS) to our leading portfolio of containment and aseptic systems for the pharmaceutical, biotech and nuclear industries.

Design features:

- Standard width, extended width and custom sizes available

- Recirculating conditioned airflow

- Room pressurization can be changed from positive to negative using the PLC touchscreen on certain models

- cGMP design with continuous/seamless

- Bioguard wall and ceiling coatings

- Epoxy coated seamless Bioguard padded floor with radius corners

- Pre-Engineered with 3D modeling

- Welded construction

- HMI touchscreen controls

- NEMA 4X Control Panel

- VHP-ready with automated aeration phase

- Pressure controlled operator and equipment airlocks

- Easily and quickly deployable with limited site preparation

- Possible accelerated deprecation as equipment

Applications:

- Pharmaceutical: ISO 7 or ISO 8 air quality

- Semiconductor: ISO 5 or ISO 6 air quality

- Biological safety products: BSL1, BSL2, BSL2+ or BSL3

Flexibility for effective capacity utilization:

Unlike traditional clean room manufacturing space, MCRs provide the flexibility you need to meet rapidly changing market demands. Additionally, these units can be rapidly repurposed to meet the evolving needs of your business, allowing you to optimize capacity utilization.

Intellectual property protection:

The MCRs provide intellectual property protection for your manufacturing or R&D through controlled access card reader door security.

Cost effective:

Traditional clean room facilities can often require high-cost, specialized maintenance and tend to generate high utilities costs. The MCR’s selfcontained design allows for simple, routine maintenance. In addition, your investment and time to market are reduced by utilizing pre-engineered solutions to avoid the time and expense of custom engineering your clean manufacturing space. Our pre-engineered MCRS provide fast, flexible cleanroom manufacturing space without the considerable time and cost associated with more traditional cleanroom options.

Base specifications:

- Standard width:

- Overall: 48’L x 18’W x 9’H

- Main Room: 37’ x 17’ (with remote HVAC)

- Weight: Approx. 35,000 lbs

- Floor loading: 500 lb./square ft.

- Extended width:

- Overall: 48’L x 36’W x 9’H

- Main Room: 37’ x 34’ (with remote HVAC)

- Weight: Approx. 68,000 lbs

- Floor loading: 500 lb./square ft.

Optional communication with BMS.

Extract Technology also offers containment and aseptic solutions:

DOWNFLOW BOOTHS

CONTAINMENT ISOLATORS

SAMPLING FACILITIES

PACK OFF AND PROCESS

ASEPTIC ISOLATORS

STANDARD PRODUCT RANGE

For more information on our products, please visit our website or contact directly:

Ferry Contact Kft.

T.: +36-1-348-6000