Illig Maschinenbau GmbH

Thermoforming and Packaging Technology Equipment

ILLIG is a leading supplier of thermoforming and mold systems for thermoplastics. As an organically grown family business, ILLIG Maschinenbau offers the market's most comprehensive and varied range of thermoforming machines and tools, as well as complex production lines and individual components. With his effective packaging developments, like Pactivity®, ILLIG provides the resource-efficient and sustainable solutions of tomorrow. Since 1946, his customers have enjoyed success made possible by ILLIG systems—now in over 80 countries across the globe. The trust of his customers motivates and spurs him on to continue to serve the customers with more know-how, innovation, premium quality, reliability and comprehensive support.

Applications

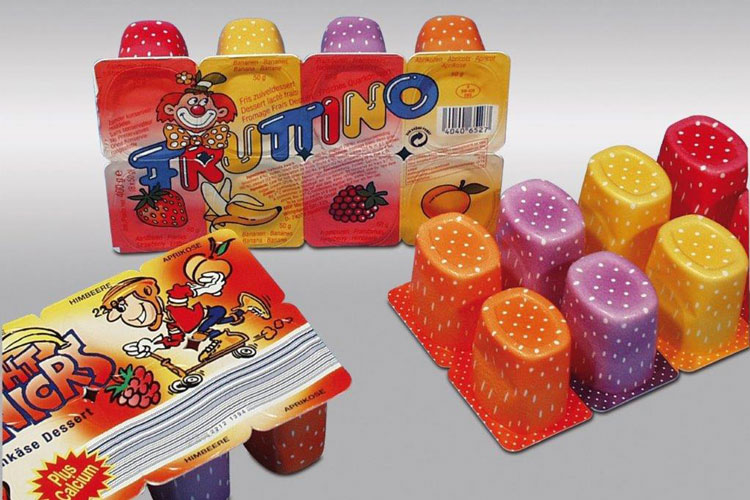

Cups

Brilliantly decorate your cups on up to five sides. Take advantage of ILLIG's know how to perfectly market your product using new and attractive concepts.

Trays

Trays and food packaging are not only functional, they also evoke emotions. They protect and market content, convey information and appeal to the senses. ILLIG enables sustainable, resource-efficient and eco-friendly packaging.

Blister packaging

Increased brand recognition with high-quality cardboard packaging, sealed with a shape-matching, transparent blister. ILLIG protects branded products with original sealed packaging.

Capsules

Custom-made packaging development in thermoforming with Pactivity®. Together with customers, ILLIG developed the first thermoformed coffee capsules. Just one example of many forward-thinking solutions.

Lids

Transparent or non-transparent form-fitting lids with appealing messages offer precision, seal-tight closure. Perfectly formed on ILLIG thermoforming systems.

Forming, filling, sealing

Standout above the competition. When you use ILLIG's form, fill and seal machines, you're in the Champion`s League of elite packaging. A packaging system for the complete process: forming, decorating, filling, sealing and product handling to meet your requirements.

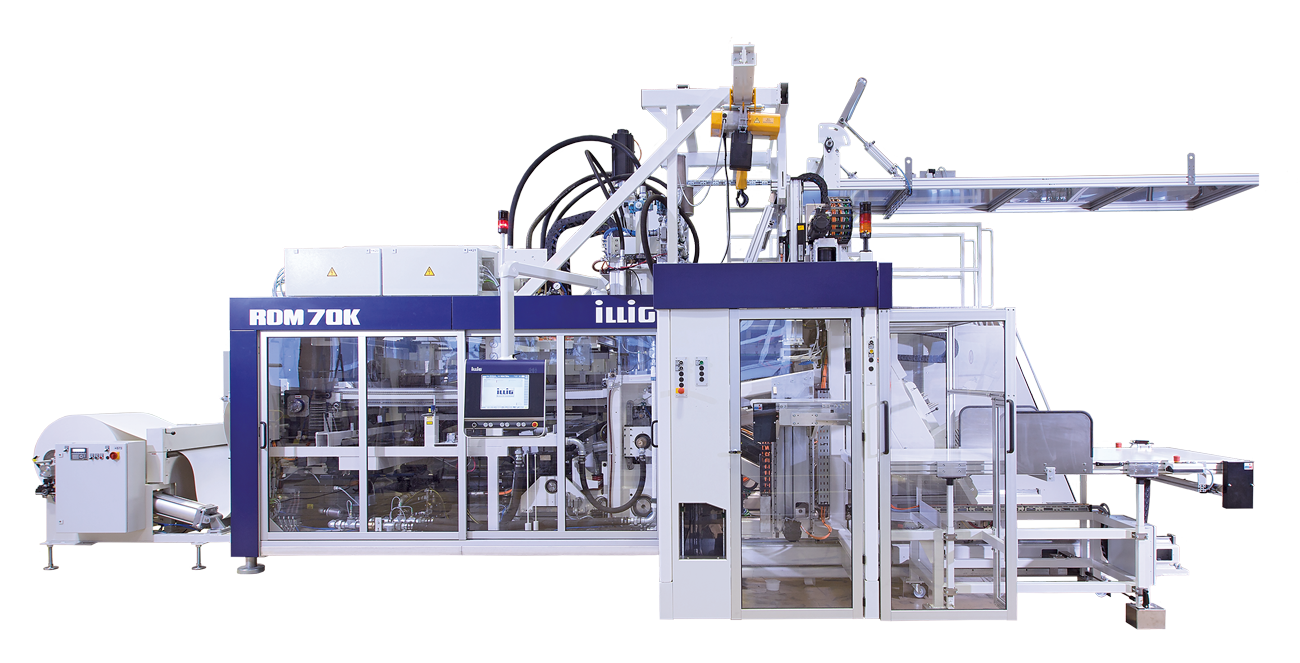

Some examples from the recent past for forward-thinking machine developments:

BF70 Bottle Forming Machine

The bottles and cups for the packaging of yoghurts, juices, vegetable, fruit and isotonic drinks are produced cost effectively by means of thermoforming. The potential to apply undergoing parts represents advantages basically both in design and use. Such parts are used as containers, for instance, filled with jams, dairy spreads, custards and fruit yoghurts. Depending on the design, the containers can be manufactured in different volumes.

Sheet Forming Machine type UAR 155g

ILLIG presents its recently developed machine, designed for thermoforming sheets. These production lines are suitable for the production of items used in different fields of application, such as electronics, entertainment electronics, automotive and vehicle industry, and general industrial application, including also household, sports and leisure items and merchandise. Every process regulated universal automatic forming machines of the UA-g series ensures a wide range of product oriented type variations and the machines with different equipment have different forming areas.

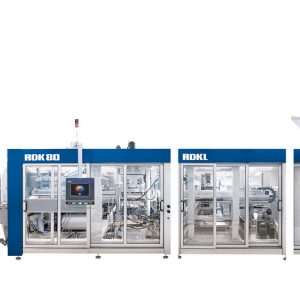

High Performance Automatic Compressed Air Forming Machine RDK 90

The largest is the new version RDK 90 automatic compressed air forming machine, suitable for the processing of even 900 mm net foil width, with 700 mm step length. Like in every ILLIG packaging technology system, in RDK 90 also the modular concept is manifested, which facilitates the purpose-made configuration of high performance thermoforming production lines with the use of diverse configuration options.

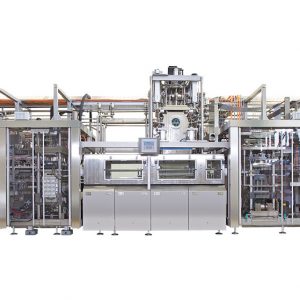

Forming-Filling-Sealing line type FSL 48 (FFS)

Simultaneous labelling on 1,2,3,4 or 5 sides is possible by means of the ILLIG FSL 48 type IML machine. At the same time, 8 different flavours can be filled and decorated differently. Despite the conventional bandage type labelling, for this technology no vertical side wall is needed. The IML module works with pre-printed labels to apply spectacular decoration on the thermoformed cups, fed from a holding stand. The many faceted application of this technology is unlimited, or just the marketing experts’ imagination may confine the application potentials.

Follow ILLIG on YouTube for the latest releases.

Gallery

Company website:

Related Industries:

Related Techniques:

Contact Us!

Have any questions? You would like us to call you back?

Send us the following blank sheet. Our staff will contact you soon.