Kurt Zecher GmbH

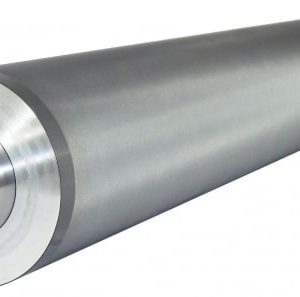

Laser engraved special ceramic and chrome cylinders for use in flexographic printing machines and in offset varnishing or laminating plants

The first regular anilox roller, for use in printing industry, was created by Kurt Zecher, in 1950. The young engineer’s innovation brought tremendous success and the company began developing dynamically. The Zecher Company is a firmly committed follower of innovation and quality principles. During the past 70 years the Company has gradually become a determining market leader in the sector.

Chrome rollers has still been used both in printing industry and in the certain fields of the coating sector (such as furniture industry). The patented diamond engraving technology of Zecher ensure appropriate cell geometries with parameters most fitting the application concerned. The special surface coating and treatment ensure long service life of the surface.

The manufacturing of the anilox rollers with ceramic coating, overcoming all challenges in flexo printing, represents cutting-edge technology. The ceramic coating is applied by means of a high-performance plasma cannon on the anti-corrosion treated rollers or composite sleeve cylinders. Engraving is made by a beam of laser as a result of which a line density of over 600 lines / cm can be achieved. The state-of-the-art ink transfer are facilitated by the special geometry of cell designs.

Engraving technologies

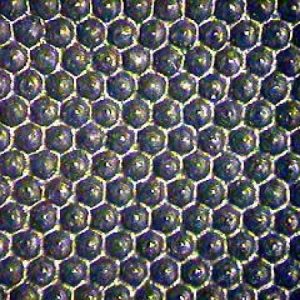

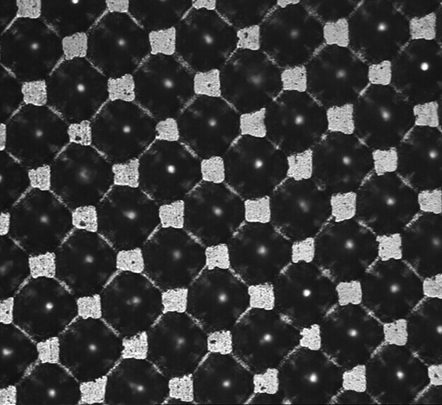

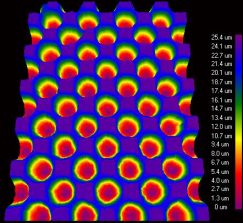

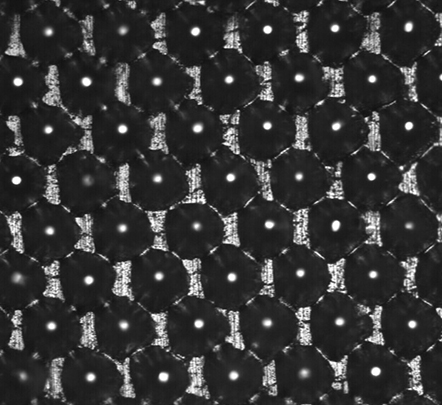

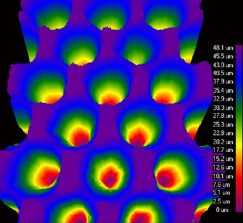

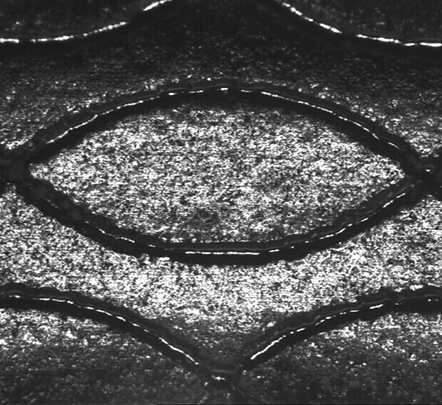

Hexa 60°

Hexa 60° is our tried-and-tested standard anilox engraving, designed to deliver top-quality printing results for both the flexo printing and coating sectors.

Diamond 45°

Diamond 45°, one of our first anilox engraving formats, has now largely been superseded by Hexa 60° technology. We nevertheless continue to recommend it for use in certain special areas of application.

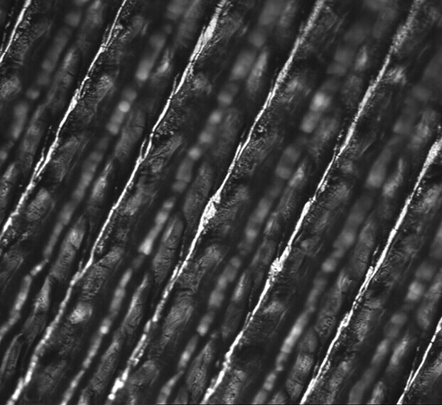

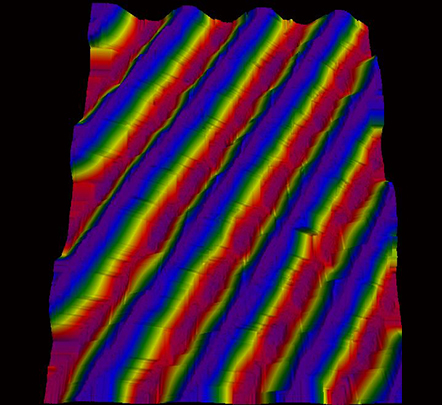

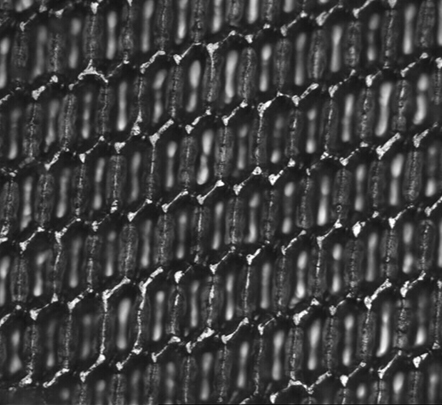

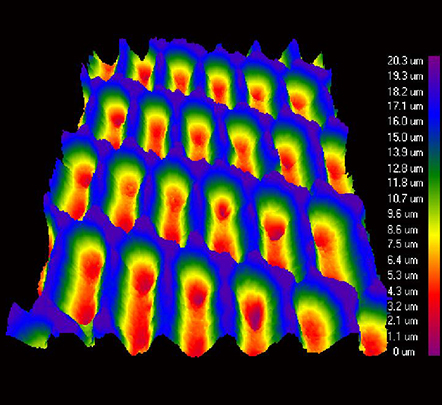

Trihelical

Trihelical (or cross-hatch) open engraving technology can be used both as a means of extending the standard range of anilox engraving techniques and as a technical alternative. The open structure of its engraved lines provides you with good transfer performance. This engraving technique is particularly recommendable if your work involves large print and coating formats.

H.I.T.

Our H.I.T. anilox engraving gives you an extra degree of white coverage, while offering new aspects of opaque white, paint coating and special colours. Our H.I.T. anilox engraving is a classic Hexa 60° engraving technique, characterized by its optimized cell geometry. Our H.I.T. engraving technique also offers you increased ink-transfer for a lower given quantity. We can particularly recommend this anilox engraving for offset-print coating units and coating machines.

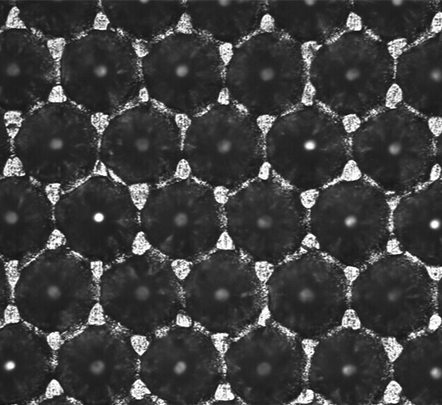

SteppedHex

Our innovative SteppedHex engraving technique, with its unique anilox cell structure, allows you to increase line-count without any loss of volume. You can therefore print with a finer raster, but without having to worry about any significant loss of solid density. You can use this anilox engraving technology with all inking systems.

Customised engraving technology

Our customized engraving technology allows us to supply you with tailored anilox roller configurations matched to your particular needs. Thanks to individually created TIFF files, we are able to laser engrave customer-specific designs on your behalf. If your work involves special formats and areas of application, our customized anilox technology is the right choice for you.

Surface finishing

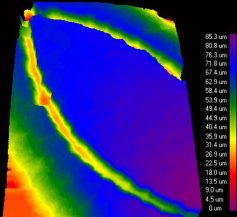

Our I.T.S.® surface finish alters the molecular structure of the ceramic material to make it denser. It is not a coating or sealing process, but is based rather on a special plasma-technology vacuum procedure that acts on the structure of the chrome or ceramic layer to create certain surface properties.

This delivers decisive benefits for your anilox rollers, including:

- Lower printing-ink penetration

- Better emptying performance

- Easier cleaning

- Increased service life, even for chrome rollers

Anilox cleaning

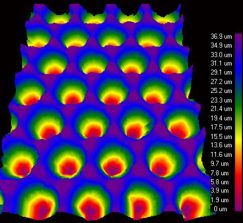

The cells on the anilox roller can become clogged with ink residues during use, which reduces the volume of the anilox cells concerned.

Regular care lets you extend the service life of your anilox rollers and save the money that you would otherwise have to spend prematurely on new ones.

Our “Zecher Anilox Cleaner” is offered in four different variants: Aqua/UV Ink, Gel, In-Line, Washing Machine and it allows a gentle and at the same time efficient cleaning of your anilox rollers.

Gallery

Videos

Related information

Business website:

Relatd industries:

Related Techniques:

Contact Us!

Have any questions? You would like us to call you back?

Send us the following blank sheet. Our staff will contact you soon.