New development at Zeller and Gmelin

Deinking project of Uvacurid C81 printed cups and bringing back the “cleaned” material in the process.

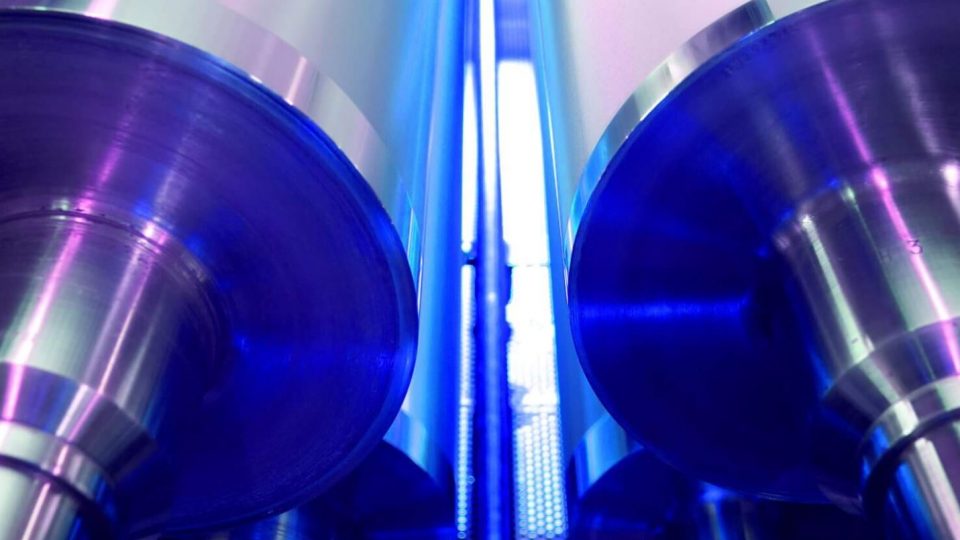

As part of environmental protection and sustainability, Zeller+Gmelin has developed a new process - decolorizing plastic cups printed with UV printing ink and recycling the cleaned plastic into production.

The results are clearly encouraging:

- Printed / crushed plastic cups, after 60 minutes of cleaning process at room temperature can be easily rinsed with tap water

- After filtration, the washing liquid (water-based / alkaline) can be recycled for further washing cycles

- The cleaned material -PP or PS- was used to produce cups (extrusion than and then thermoforming). The cups were tested by migration analysis and found no migration potential, coming from ink

- With this method, we can offer a realistic solution for recycling of printed waste in cup production