Self-cleaning HEPA filter systems

We would like to introduce you one of the product of Containment Technology GmbH represented by us.

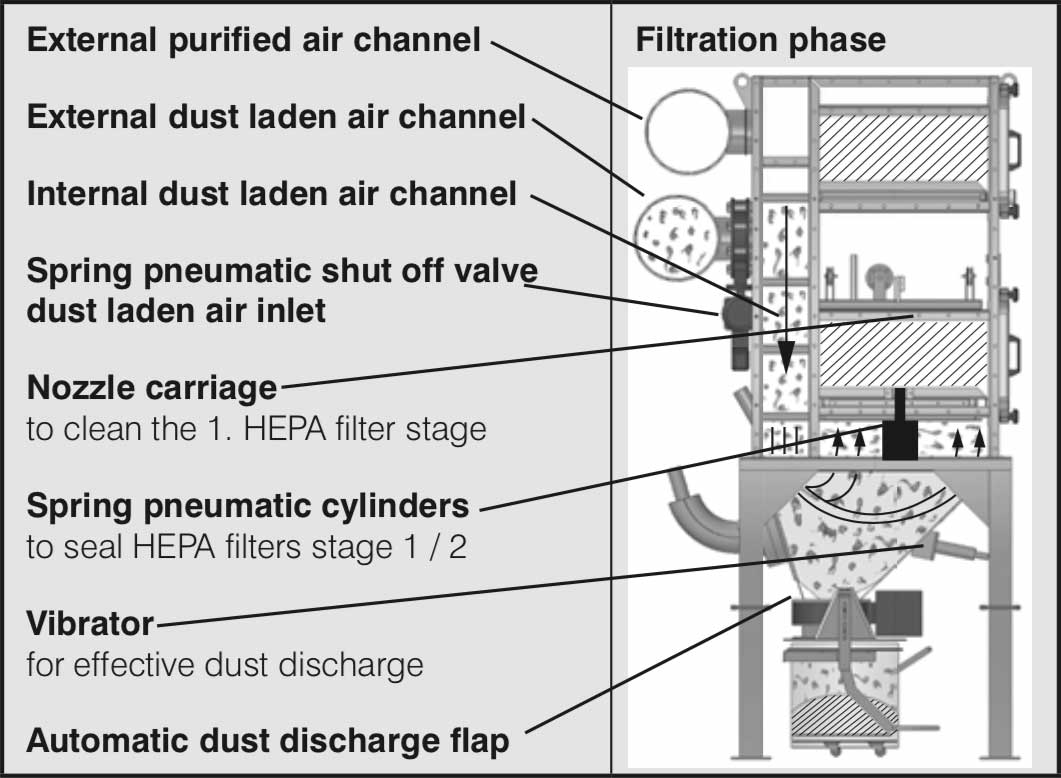

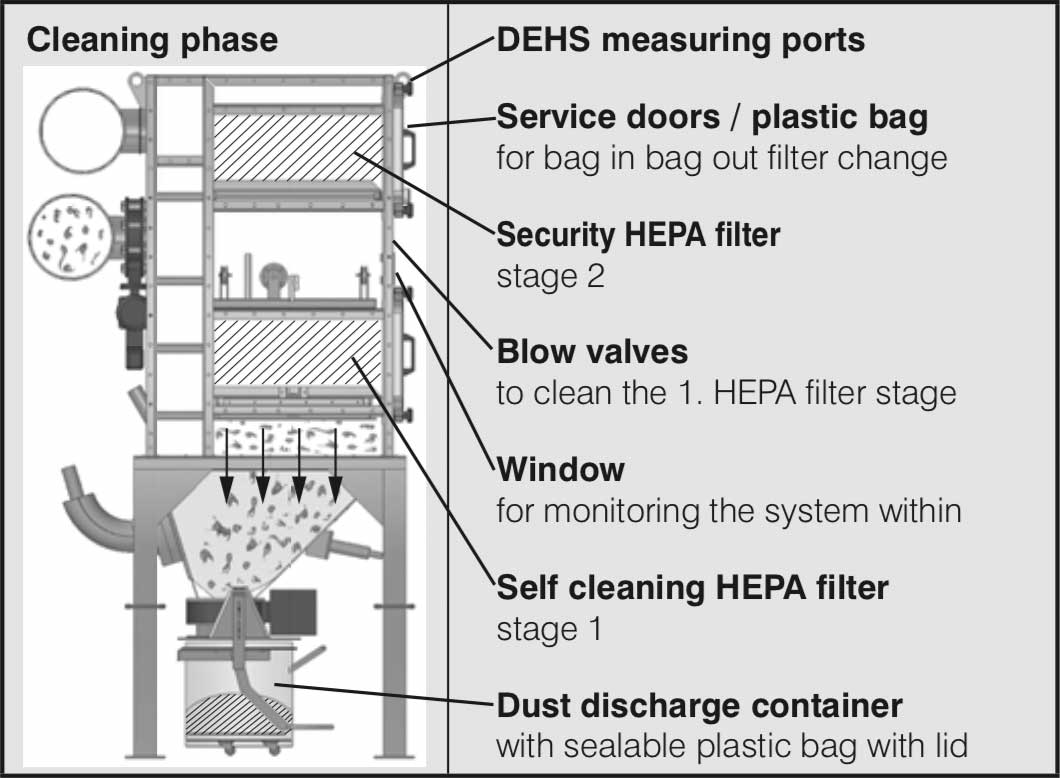

Construction of the filter system

Origin of the HEPA filter system

The construction of the body of the self-cleaning HEPA filter system derives from the filter units engineered for the filtration of radioactively charged dusts.

The HEPA filter system applied to filter radioactively charged dust from atmospheric air was further developed in the 1970ies by Mr. Kalman Andrasfalvy sen. for the filtration of dust laden process air with even highest dust loads.

Today

the self-cleaning HEPA filter system is adapted to the special needs in the

- Nuclear industry

- Chemical-Pharmaceutical industry,

- Food and Cosmetics Industry,

- General industries with hazardous to health dusts.

In general, the self-cleaning HEPA filter system provides:

Explosion prevention

Special attention has been paid to explosion prevention and explosion protection, so that the self-cleaning HEPA filter system does not underlie the ATEX Directive 2014/34/EU.

It can be used safely without explosion venting and suppression systems.

It can be installed inside the production rooms together with all other production machines, as no explosion danger is to be expected.

Containment Solutions:

Protection of the operator and environment as well as prevention of cross-contamination.

- Highest possible filter efficiencies of H14 / EN 1822.

- Lowest possible contamination when handling the system OEB 1-6

Function of the self-cleaning HEPA filter system

The filter system has been designed in a way that it can effectively filter even highest dust loads of up to 100 g/m³/h with coarse and finest respirable dusts by means of a cyclone effect, whereby the coarse dusts are separated in advance.

The HEPA filter cassettes stage 1 filter the dust laden process air remaining after the filtration of the cyclone effect within. The individual police filter stage 2 in each module guarantees a constant separation efficiency H 14 according to EN 1822.

The cleaning of HEPA filter cassettes stage 1 takes place off line in each module individually. The other(s) remain in operation, so that a constant filtration with an off line cleaning becomes possible.

The dedusting intervals are initiated according time intervals, and can be set actual requirements.