Flexo Concepts

Revolutionary doctor blade technologies for the printing industry

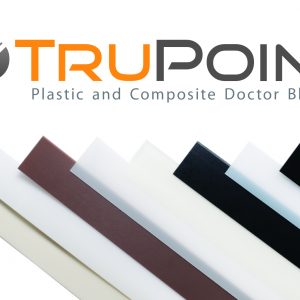

Flexo Concepts introduced the first TruPoint™ doctor blade to the printing industry in 1989. The aim of Flexo Concepts is to meet the needs of offset and flexo printing presses through the introduction of smart solutions which increase printing quality, reduce costs and the wear of the screen roller and increase work safety. In addition to manufacturing excellent quality products, maintenance of a professional customer service is of outstanding importance. We strive for establishing a seamless relationship with the customer and to allow him to focus on the growth of his business.

Application

TruPoint™ Orange

TruPoint™ doctor blade is a cost-saving and practical alternative to the steel doctor blades in flexo printing. It is made of different polymer and composite materials, hence the TruPoint™ doctor blade can have an even five times longer life cycle than the steel alternatives, and it can pass all types of printing ink and lacquer more efficiently. In addition, the TruPoint™ doctor blade reduces the risk of scratching on the anilox roller and is safer to handle than the conventional steel blades. All this means less servicing of the anilox roller and minimized risk of injury (safer operation) to the operator. With newer printing techniques and the increasing customer needs it is important that the pressman chooses the right doctor blade material in order to ensure the best printing quality and to minimize costs.

- constant ink and lacquer thickness

- longer service life, less frequent replacement

- less scratches on the anilox roller and longer roller service life

- less risk of damages when replacing the doctor blade

- Infeed of all types of ink and lacquer is possible

Gallery

Videos

Related information

Business website:

Relatd industries:

Related Techniques:

Contact Us!

Have any questions? You would like us to call you back?

Send us the following blank sheet. Our staff will contact you soon.